Customers Who Bought This Item Also Bought

overview

Electroformed Framed Stencils are nickel-based, electroform foils designed to work with stencil tensioning systems also known as Reusable Stencil Frames. They do not need to be permanently glued in a frame.

Electroformed stencils offer the best paste release characteristics available and are frequently used for fine pitch (20 mil to 12 mil pitch) SMT applications on printed circuit boards. They are also used for µBGA's, Flip Chip, and Wafer Bumping (12 mil to 6 mil pitch).

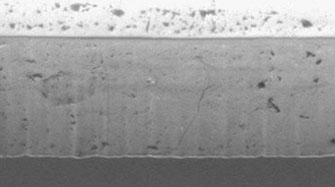

Nickel Stencil Production Electroforming creates a nickel stencil with a unique gasketing feature that reduces solder bridging and minimizes the need for underside stencil cleaning. The stencil is created by imaging photoresist on a substrate (or mandrel) where the apertures are intended and then plating - atom by atom - the stencil around the resist to the desired thickness.

The nickel atoms are deflected by the photoresist to create a trapezoidal configuration. When the stencil is removed from the substrate, the top becomes the contact side to create the gasketing effect. This process provides near-perfect registration with no geometric limitations, smooth vertical side-walls with a built-in taper and low surface tension to enhance paste release.

Laser Cut Aperture Wall

Electroformed Aperture Wall

Main Features

- The smooth trapezoidal sidewalls of an electroformed stencil allow for better paste release compared to polished laser or etched stencils. They provide fine and ultra-fine pitch apertures with paste transfer efficiencies at 95% and above.

- Electroform foils are harder than full hard stainless steel of comparable thickness, providing for longer stencil life (hardness 500 Hv and greater). This durability is advantageous for high-volume runs.

- Large aperture counts can be completed faster and more efficiently with an electroform stencil due to the electroform process itself. This allows for a denser image area without any distortion due to heat transfer caused by laser cutting. (pad count: 1 to unlimited)

- Allows for thinner stencils due to the increase in paste transfer efficiencies. Available in 1 to 12 mil thicknesses with 0.1 mil increments.

- Superior printing characteristics and lower defect rates guarantee high process yields

AVAILABLE SIZES

| Frame Size | Max. Foil Size | Max. Image Size |

| 8”x10” ID Cast | 6”x8” | 4”x6” |

| 12”x12” ID Cast | 10”x10” | 8”x8” |

| 12”x17” ID Cast | 10”x15” | 8”x13” |

| 15”x15” ID Cast | 13”x13” | 11”x11” |

| 20”x20” ID Cast | 19”x19” | 17”x17” |

| 23”x23” OD Tubular | 19”x19” | 17”x17” |

| 23”x27” OD Tubular | 19”x23” | 17”x21” |

| 24”x24” ID Cast | 22”x22” | 20”x20” |

| 29”x29” OD Tubular | 24”x24” | 22”x22” |

| Fuji (all syles) Tubular | ||

| Cast frames are solid aluminum. Tubular or Extruded frames are hollow. | ||

specs

| Technology | Electroforming |

| Material | Nickel |

| Suitable Applications | All Component Pitches |

| Aperture Dimensional Tolerances | ± 0.0003” |

| Thickness Available | 0.001” - 0.006” All thicknesses are available at increments of 0.0001” increments. |

| Positional Accuracy | ± 0.0003” |