Stencils Unlimited manufactures wave solder pallets in our state-of-the-art facility in Tualatin, Oregon. All our pallets are made with Durostone®, a heavy-duty (Electro-Static Discharge) ESD composite material that exhibits good machinability in addition to the following characteristics:

- Withstand high temperatures and resist the corrosive effects of solder and flux.

- Low heat and moisture absorption.

- Dimensional stability for proper board alignment.

Gallery

Quoting and ordering your Wave Solder Pallets online!

You can request a custom quote or quote and order your pallets online. Please follow the next steps to quote and order online.

- Enter the part number and revision of your pallet. It is very important to assign a part number and a revision to any custom part for identification.

- Attached a zip file containing the following information:

- Gerber or Step files

- Photos of previously assembled boards (if available)

- Special instructions

- Select the material type and thickness. If you are not sure what to select, please request a custom quote.

- Enter the approximate pallet length and width in inches.

- Enter the number of hold downs. We recommend a minimum of two hold downs for individual boards. If your boards are panelized we recommend four hold downs, one for each corner of the panel.

- Select “Yes” if your pallet needs a top hat.

- Select “Yes” if you would like to add stiffener bars to your pallet.

- Please enter the number of shoulder bolts to be added to your pallet.

- Enter the number of pallets you would like to order in the “Quantity” field in the upper right corner of the screen. An automatic discount is applied depending on the quantity.

Wave Solder Pallet Fabrication

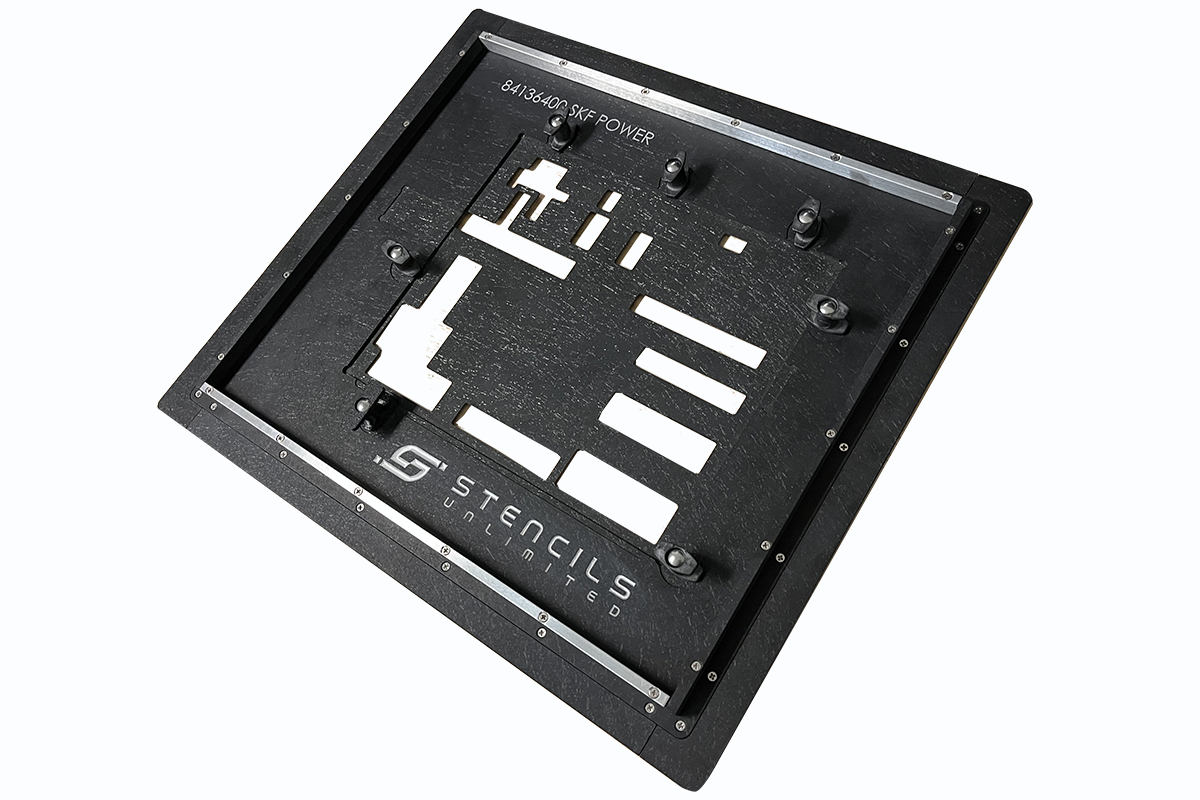

Our technicians use the latest technology in CNC machining to fabricate wave solder pallets. Fabrication mainly consists of removing material from areas of the pallet where the circuit board is to be exposed to the wave, and solder is required.

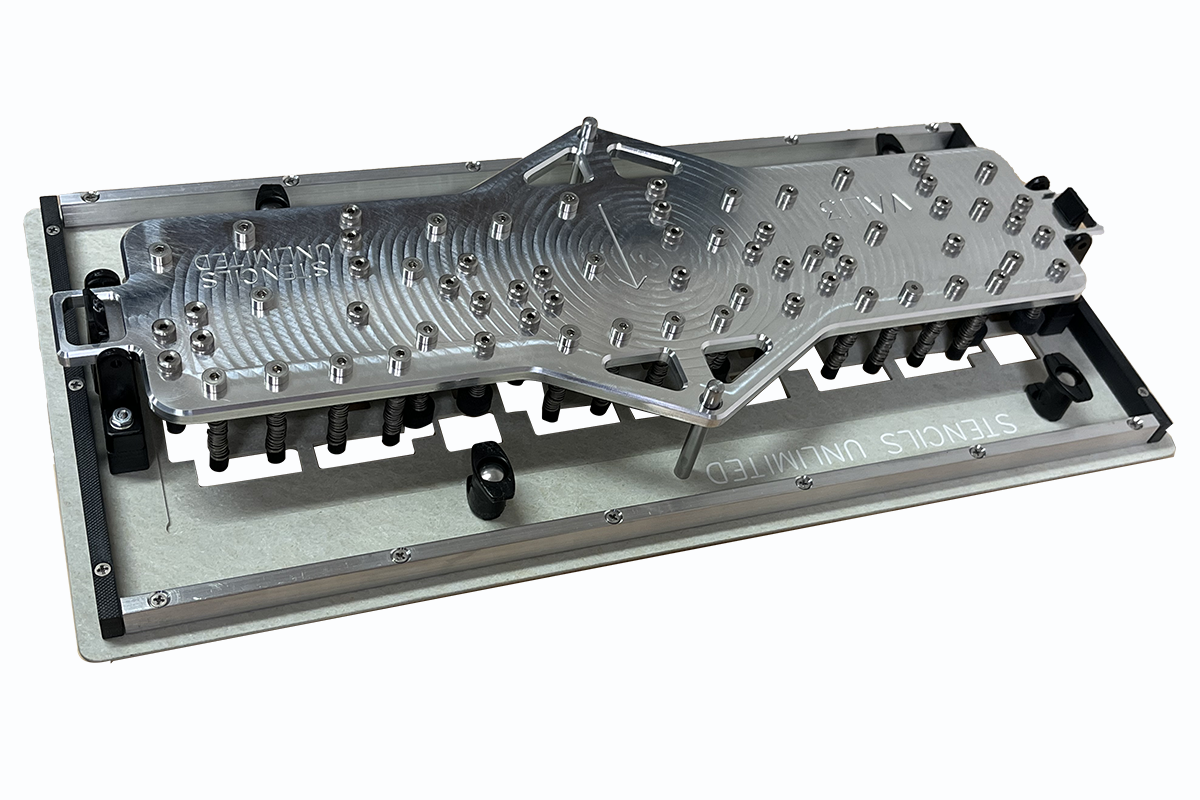

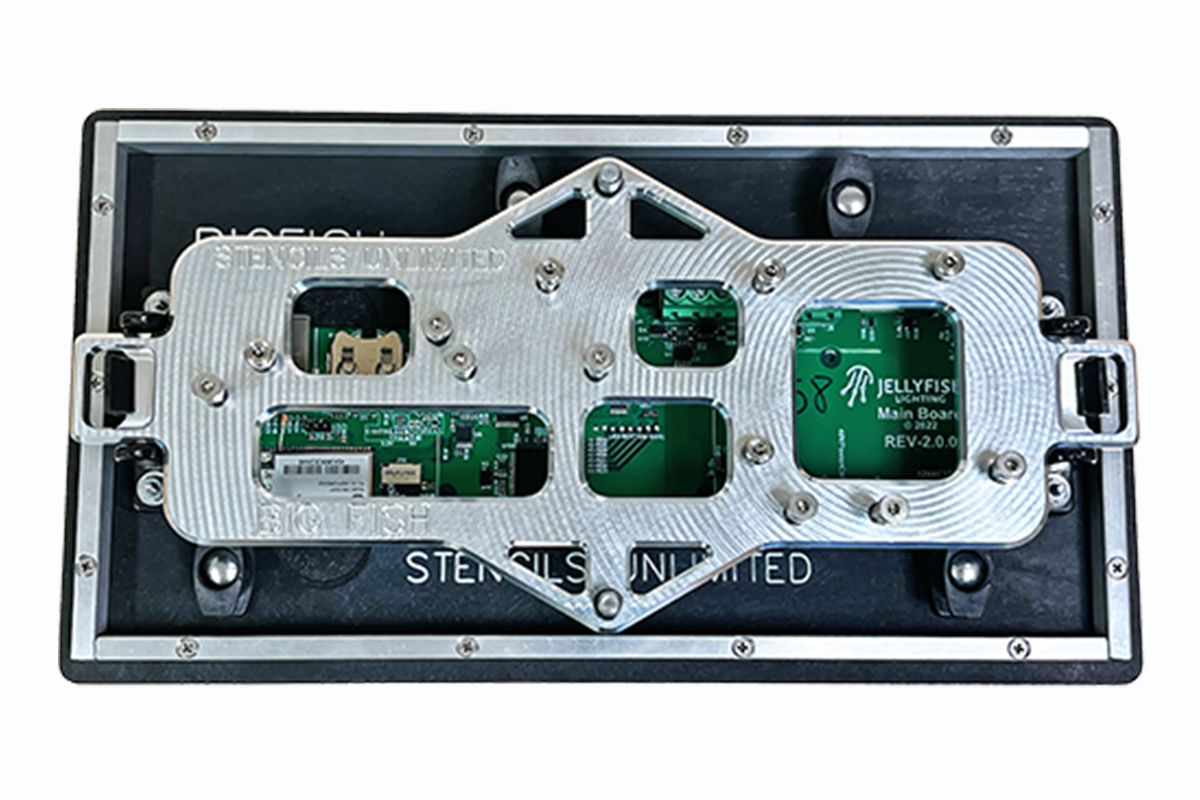

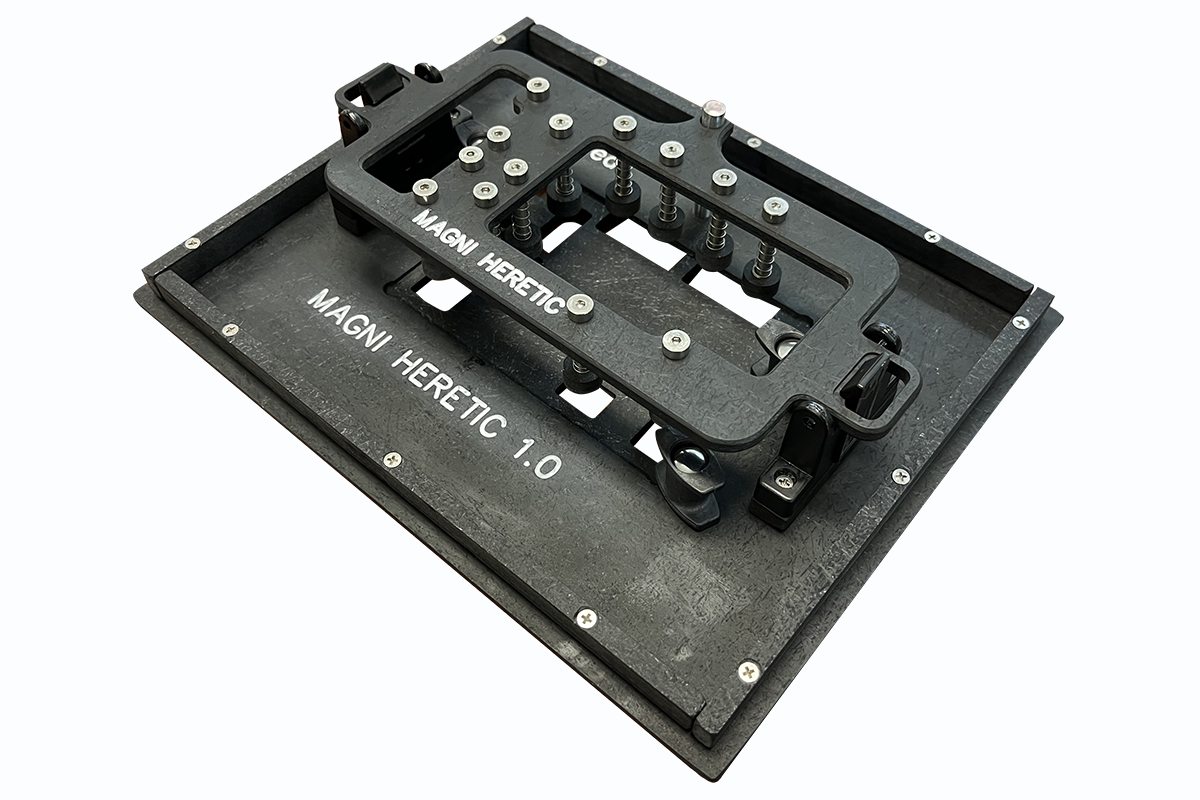

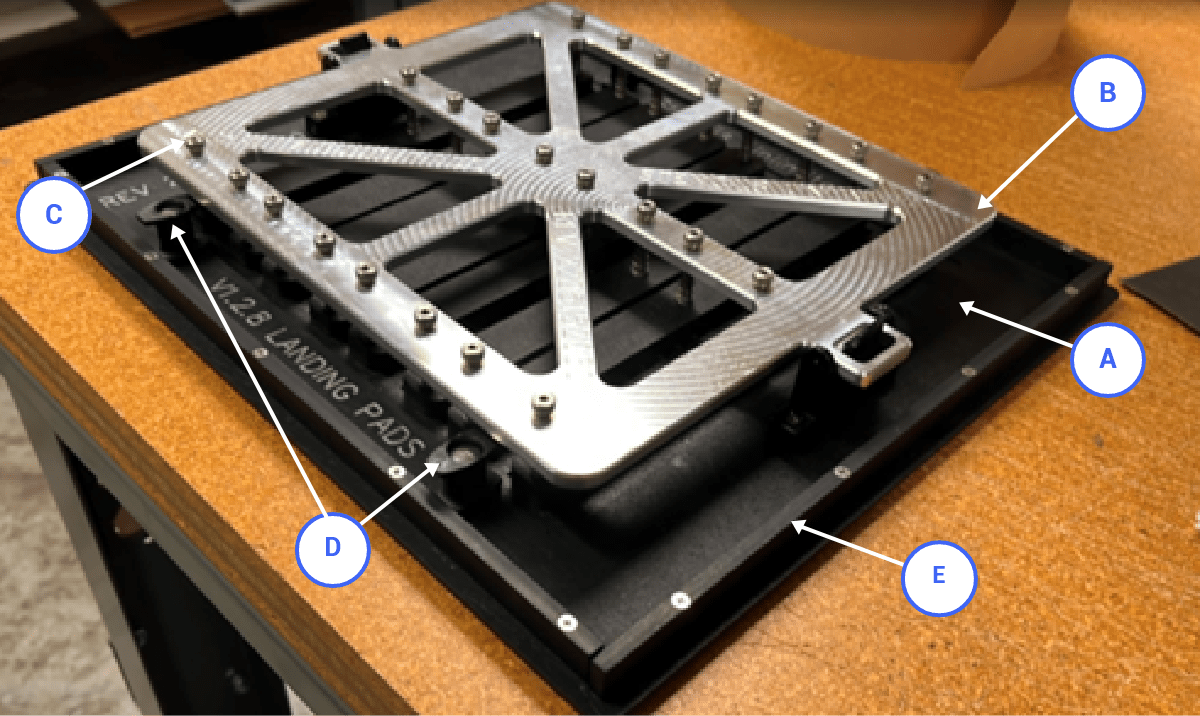

Every wave solder pallet is custom designed to fit a specific PCB layout and meet unique process requirements however, they usually have the following components:

A) Base plate: Also known as base pallet serves as the foundation for the pallet and provides a flat surface for the PCB to rest on during soldering. It typically features cutouts and openings that allow the solder to flow through and create the necessary solder joints, while protecting the components from being damaged.

B) Top hat: Also known as Cover Plate, is designed to hold the components in place during wave soldering and sits on top of the Base Plate. It typically features openings to reduce weight.

C) Alignment dowels: They are used to ensure the Top Hat is correctly positioned above the PCBs.

D) Hold downs: They hold the PCB securely in place. They are commonly made of titanium and plastic instead of steel to avoid cross contamination.

E) Stiffener Bars - They are used to provide support to the pallet to reduce twisting and bending. They also prevent solder from going over the top area of the pallet.

F) Gas relief: Also known as vent holes are indentations on the pallet to allow gases to escape during soldering. They also help to prevent defects such as solder voids or insufficient wetting, which can occur when gases become trapped in the solder joint.