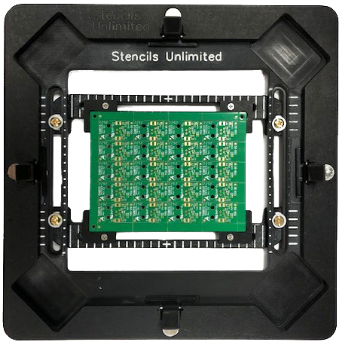

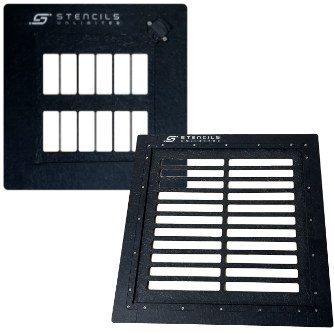

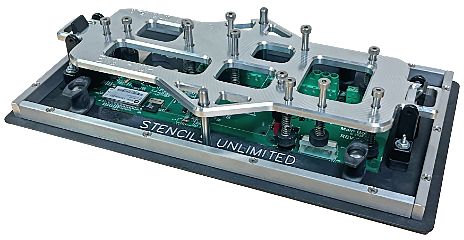

PCB assembly fixtures (also referred to as PCB assembly tooling) are used to support and protect the printed circuit boards and electronic components during the PCB assembly process. Our SMT carriers and wave solder pallets are made with Durostone®, a heavy-duty (Electro-Static Discharge) ESD composite material. This material exhibits good machinability and is able to withstand the high temperatures and the chemicals associated with soldering applications.

Our technical team uses state-of-the-art CNC machines to fabricate our PCB assembly fixtures.