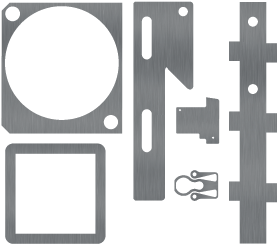

Precision flat washers, shims and spacers

24-48 HOUR SERVICEStencils Unlimited offers customized precision flat washers, shims and spacers on a variety of materials. We use advanced laser technology to fabricate ultra-precision products with burr-free and stress-free finishing.

- Precision laser cutting manufacturing (laser engraving available)

- A variety of materials, sizes and thicknesses

- Burr free and stress free

- No tooling

- No minimum quantity

- Short Lead Time

Overview

Flat washers, shims and spacers are used as temporary or permanent solutions in many applications. They are commonly used to fill small gaps and to provide support between parts. They can be also used as leveling parts or alignment tabs. We use precision laser cutting technology to eliminate the need for tooling and thus reducing the manufacturing cost and the lead time. Our lasers can cut with high precision the most detailed features without burning or warping the material. We can cut features as small as 0.002".

Although we can fabricate flat washers, shims and spacers in a variety of materials they are usually ordered in stainless steel. We stock 0.002" - 0.020" stainless steel sheets.

| Technology | Precision Laser Cutting |

| Materials | Stainless steel * |

| Lead time | 24-48 hours |

| Material thicknesses | 0.002" - 0.020" * |

| Minimum feature size | 0.002" (50 um) |

| Maximum size | 22.5"x29" |

| Aperture tolerance | Within .00025" |

| Engraving | Yes |

Preferred Data Formats

There are many forms of acceptable data. The following is a list of data formats that are acceptable for laser design files to be submitted in: Gerber, DXF, HP-GL, and HP-GL2 are the primary formats accepted. Please note that it is a good idea to include a PDF drawing of the data provided for reference. We can always send a check plot before proceeding to manufacture.

*Other materials and thickness available upon request.