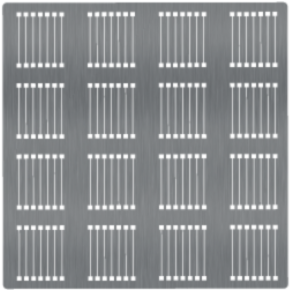

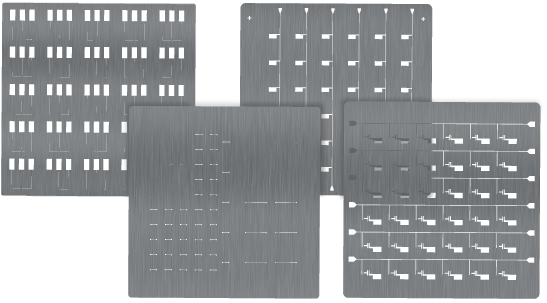

Shadow Masks

24-48 Hour ServiceStencils Unlimited offers shadow masks (also known as deposition masks) in a variety of materials, sizes and thicknesses. We use advanced laser technology to fabricate ultra-precision products with burr-free and stress-free finishing.

- Ultra-high Precision laser cutting manufacturing

- Minimum width of features of 25 um

- Aperture tolerance within 6.35 um - A variety of materials, sizes and thicknesses

- Burr free and stress free

- No tooling (lower cost & lead time)

- Laser engraving available

Overview

A shadow mask is a micromachined template (typically a laser cut or chemically etched thin sheet of metal) use to deposit material onto a substrate. Deposition mask techniques are used in a wide range of vacuum-chamber evaporation and sputtering processes to fabricate both simple and complex micro-engineered electronic components and products. They are increasingly being used to deposit inks onto substrates during the manufacture of flat panel displays or for the deposition of metal electrodes on polymer, glass or ceramic substrates. We can fabricate shadow masks using thicknesses between 0.002" and 0.020".

Precision Laser Cutting a Shadow Mask using an Infrared Laser.

| Technology | Laser cutting |

| Materials | Stainless steel * |

| Lead time | 24-48 hours |

| Material thicknesses | 0.002" - 0.020" * |

| Minimum feature size | 0.002" (50 um) (circles and lines: 25um) |

| Maximum size | 22.5"x29" |

| Aperture tolerance | Within .00025" |

| Engraving | Yes |

Preferred Data Formats

There are many forms of acceptable data. The following is a list of data formats that are acceptable for laser design files to be submitted in: Gerber, DXF, HP-GL, and HP-GL2 are the primary formats accepted. Please note that it is a good idea to include a PDF drawing of the data provided for reference. We can always send a check plot before proceeding to manufacture.