Made in the USA

Made in the USA

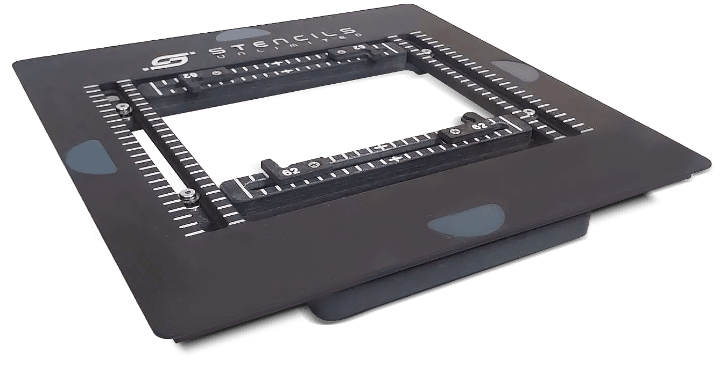

We manufacture the prototype SMT stencil fixtures in our state-of-the-art facility in Tualatin, Oregon. They are manufactured with a heavy-duty (Electro-Static Discharge) ESD composite material. The prototype SMT stencil fixture comes with:

- An adjustable board fixture

- A stencil fixture

- A registration fixture

Specifications

| Small Fixture | Large Fixture | |

|---|---|---|

| Dimensions | 10"X 10" | 20"x14" |

| Min PCB Size | 1.25"x1.75" | 1.25"x1.75" |

| Max PCB Size | 5"x 5.75" | 13.5"x8.5" |

| SMT Stencil Sizes | 7"x7" | 16.14" x 10.14" |

The Board Fixture

It contains fixed and sliding bars as well as PCB holders to provide board support. The fixed and sliding bars have a grid to help position the board on the fixture. It also contains rubber feet on the bottom side to enable double side printing and prevent the fixture from moving during the print process.

The Registration Fixture

It can be rotated or moved vertically and/or horizontally to achieve perfect registration. It comes with

powerful magnets to keep the fixture from moving during the printing process.

It also has four levers to lift the stencil fixture vertically to prevent the paste from smearing.

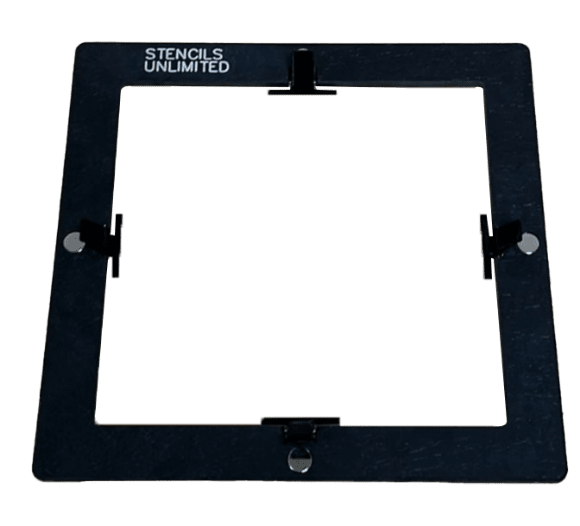

The Stencil Fixture

It has four aluminum bars to hold the SMT stencil and apply tension in all four directions for better printing. The handles on the top side are used to remove the stencil fixture to access the PCB.