Screen Print and Reflow your prototype circuit boards

by Bob RooksA Surface Mount Overview

Every day seems to offer new Surface Mount Devices (SMDs) that tantalize you with a wealth of capabilities you can't find in through hole components. In fact, many types of through holes are getting harder to find as time goes by because Surface Mount Technology (SMT) is a more profitable process for large manufacturers. SMT gives them higher device capability and it's streamlined to fit right into automated assembly. Device manufacturers are following the money. Although it looks like some through holes will always be around, most are disappearing. There just isn't enough business in through hole parts to justify making most of them anymore.

Because the length of the traces are shorter on SMT devices, they offer a real advantage in high frequency applications. You also get more function on any given piece of real estate, which probably drives surface mount more than anything else.

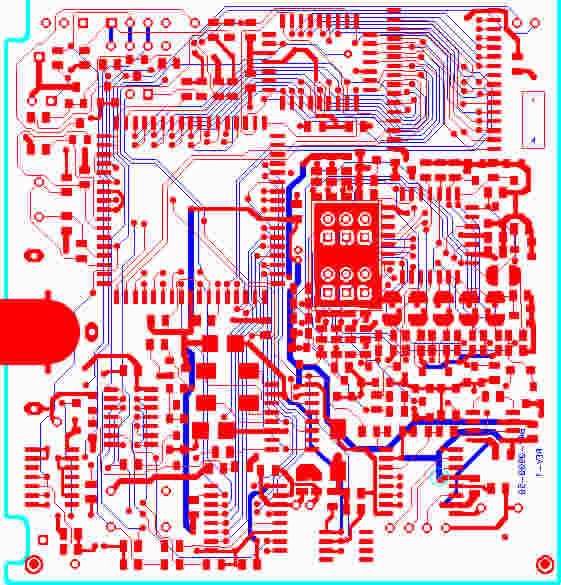

Basically, what you can build with surface mount goes far beyond what you can build with through hole as the following SMT schematic illustrates.

Still, purely surface mount may never be a reality because even digital boards have connectors to plug them into the world. Connectors produce exceptional stress on the solder joints which is a negative for SMT. Compared to through hole, SMDs are easier to rip off the board. So, until somebody fixes this problem, components like connectors will continue to rely on basic through hole technology. In the plant, this means they wind up reflow soldering the SMDs and use wave or selective soldering for connectors and some analog devices.

The larger size of solder joints and wide spacing between leads on through hole boards are easy to handle for anyone familiar with hand soldering. Soldering the tighter pitch on surface mount devices is the main problem for a home workshop.

Enjoy SMD capabilites using the at-home procedure outlined here

In defense of SMDs, printed circuit board has glass fibers in it arranged in an X-Y direction, not in the Z direction. The coefficient of thermal expansion in X-Y is much less than it is in Z. So whenever you touch a solder iron to the board it expands more rapidly in the Z direction, causing stress in the barrels of plated through hole and via. This stress can crack the copper barrel where it joins the pad on the board surface. SMD boards are more reliable in this area than through hole boards.

Home Workshops and SMD Assembly Problems

You'd like to take advantage of some of the newer SMD capabilities, but may have avoided it because of the problems associated with hand soldering the leads. To compensate, many of you will have mixed technology boards built to your design spec and then send out to have them assembled at a contract shop. This can add a lot of time and expense to your project unless you're really lucky and have a buddy or a long standing relationship with a local shop that will put your one or two boards at the top of their production schedule.

You know that screen printing your solder paste and reflowing your assembly is the method you would choose if you could. But, to date, nobody has a screen printer or reflow oven that would even fit on your workbench - let alone, be affordable.

Well, guess what? Now you have both. The following method I'm going to take you through is far from the sophistication of major screen printing and reflow equipment, but it gets the job done - even double sided SMT boards. You can do it right in your garage or workshop. It's possible to actually cut your assembly time, increase the quality of your designs and open the door to all the mixed technology you want to experiment with.

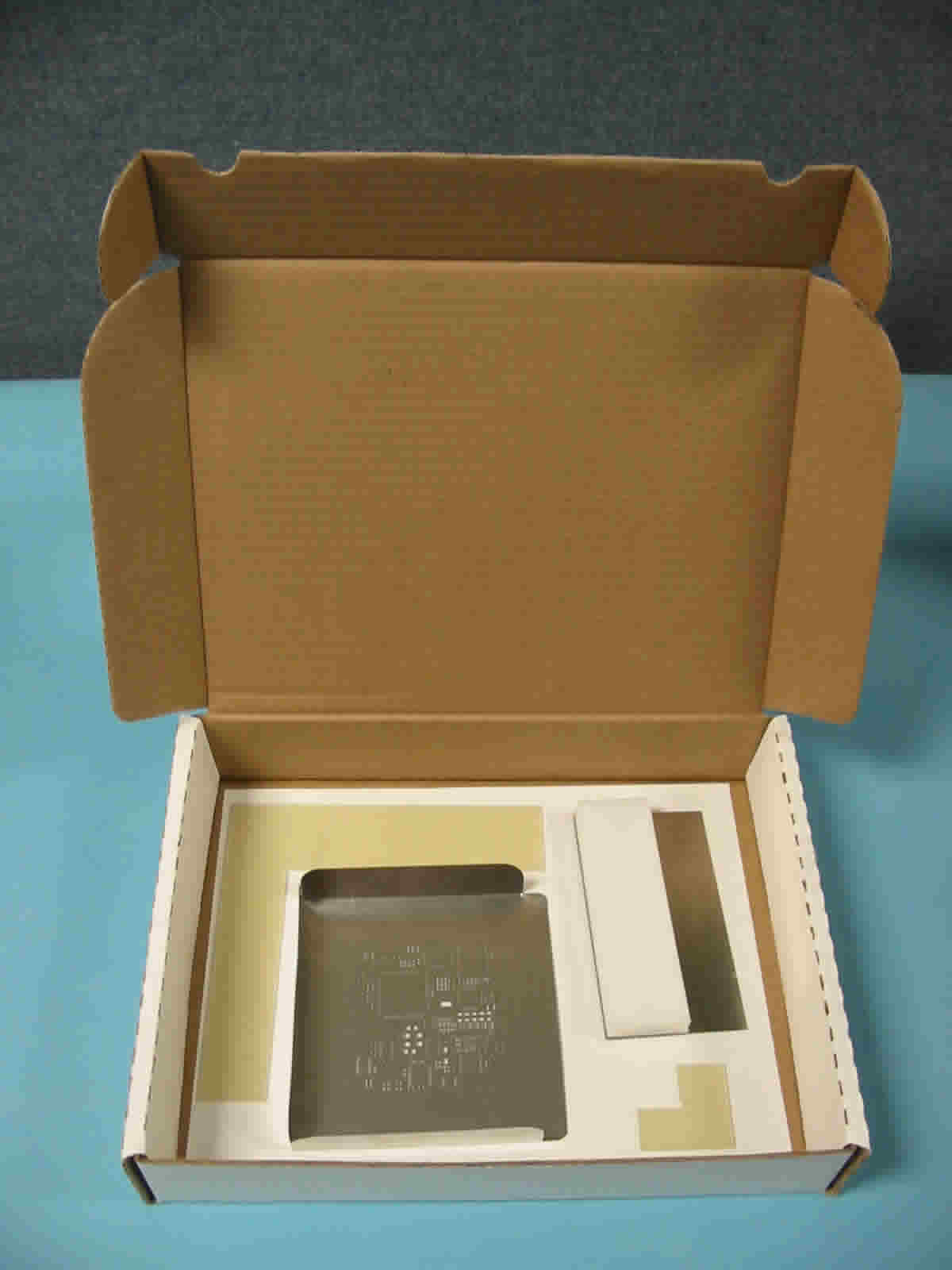

I'll take you through all the steps using a new prototype stencil tool developed specifically for your home shop and (don't laugh), a common toaster oven. Face it, building SMT boards at home will never be a 'piece of cake', but this new procedure should help make it a lot easier and maybe save a little time and money by keeping more of your project in-house. Here's what I'll be working with:

Reflow Temperature Indicator

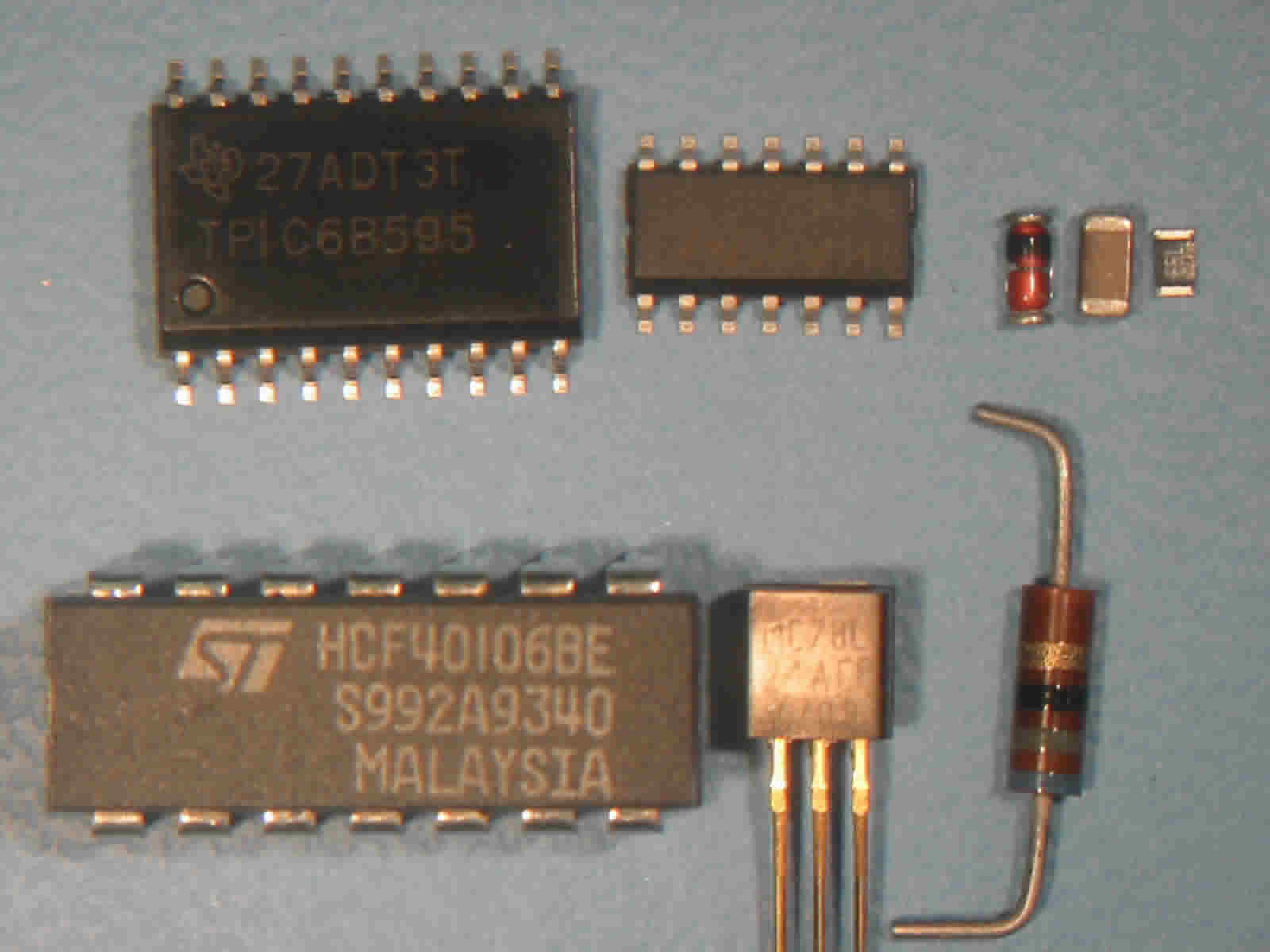

SMT Components

Printed Wiring Board (PCB)

Squeegee

SMT Placement Tools

Toaster Oven

These products and materials are available from PCBexpress (www.pcbexpress.com), a vendor that I use to build my PCBs. Regardless of what vendor you select, all tools in home stencil kits would basically work in the same way. There are only so many low cost ways to screen print at home - and, a toaster oven is a toaster oven. Most sources have at least two levels of kits available. What you want depends on how "single source" you like to be. Of course, all kits offer complete "How-To" instructions.

Ordering your PCB and Prototype stencil

First, you need to get your prototype stencil made. Although they're not just for prototype products, I like to call these stencils "prototype" to differentiate them from standard framed production stencils. These "frameless" type of stencils run from 50% to almost 85% less than the cost of conventional stencils.

You can have both your board and stencil made by a single vendor as I did or, if you already have your boards, there are vendors that will just make stencils. In the past, I've purchased prototype stencils for existing boards from Stencils Unlimited on the internet (www.stencilsunlimited.com) and I'm sure there are others you can find with a simple web search.

- Prototype stencil

- Squeegee Blade

- PCB Holders

- Solder Paste

- Reflow Temperature Indicator

To order a stencil, you need to send the vendor your Gerber files just as you always do to get your design made up, but in a little different way if possible. When you send in your board design, indicate both the silk screen and solder paste layer in your Gerber files. The PCB or service will take those files and create the prototype stencil pattern from them.

Some of you may not have a software program that can create the silk screen and stencil layer files. In this case, the vendor can use the top and bottom copper Gerber files and edit them to create the pad openings in the prototype stencil that match your board design. It's a little more involved, but a common practice - even in professional run production. The big electronic contract shops run into this all the time, so don't fret if you don't have the capability to create these special files. Any good PCB or frameless stencil vendor does.

Considerations Regarding Solder Paste and Components

Solder Paste: There are lots of solder paste manufacturers. Some don't provide printable paste in containers less than 500 gr. For a small number of PCBs this would be expensive. What you want is standard eutectic tin/lead solder. This is typically available in either small jars or in the syringes that are typically used in rework stations. Most vendors providing home prototype stencils will have small jars of solder paste available, like the one in the following photo. Be sure to check on this. Solder paste in small quantities cost around $0.25 to $0.50 per gram.

Paste for rework typically comes in 100 gr. syringe sizes, but also has a lower percent of metal so the paste will flow through the syringe easier. Repair paste may slump on fine pitch components causing solder shorts. On QFPs you may have to clear solder shorts with a fine tip solder iron. Because of this, some manufacturers do not recommend using this type of paste for screen printing applications. But it's your choice.

A Few Cautions:Solder Paste: Most standard solder paste is shipped in a cold pack. It has a longer shelf life if refrigerated. Before using the solder paste remove it from refrigeration and let it warm to room temperature (DO NOT STORE SOLDER PASTE IN REFRIGERTOR WITH FOOD). If you do not have a safe place to refrigerate the solder paste store it in a cool dry place. Some prototype stencil vendors and solder paste vendors can provide a type of solder paste that does not require refrigeration, so again, be sure to check on this.

Solder paste contains lead. You have to dispose of unused solder paste and rags with solder paste on them as hazardous material. Talk to your solder paste supplier about taking this hazardous material back for recycling. If the solder paste supplier won't take this material back, he can usually tell you how to dispose of it safely.

Components: There are far too many types of SMDs to go into here. If you want it done, there is a device that can do it for you. Ask your component manufacturer or supplier.