Customers Who Bought This Item Also Bought

OVERVIEW

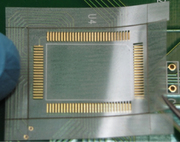

Are you frustrated by rework stencil printing? Are you having to perform multiple paste operations due to smeared solder paste or flux patterns? Is miniature stencil cleaning time consuming and frustrating? We have an answer to your frustrations--- the StencilQuick™ BGA Rework Stencils. This breakthrough method allows you to simplify area array device placement/replacement saving 50% or more of the time required to rework BGAs or CSPs.

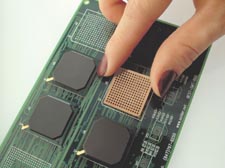

These flexible solder paste rework stencils remain in place on the site location becoming an integral part of the PCB assembly.

The StencilQuick™ BGA Rework Stencils are manufactured from a polyimide film with a high temperature adhesive covered with a release liner. It is the same type of material you have been using with bar code labels and for protecting gold fingers during the wave soldering process.

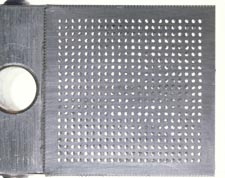

These BGA Rework Stencils are laser cut from high quality, anti-static polyimide film with a residue-free high temperature adhesive backing. The StencilQuick™ BGA Rework Stencils apertures correspond to the land patterns on the PCB and define those portions of the PCB which are to have paste or paste flux applied.

Whether you are using paste flux or solder paste the StencilQuick™ BGA Rework Stencils greatly simplifies your rework process

while providing for a more reliable connection.

For more information please refer to the following links:

StencilQuik BGA Rework Stencils were specially designed to make your rework faster and simpler.

They use a breakthrough method that allows you to simplify the placement/replacement of area array devices such as BGAs and CSPs as well as other leaded SMT devices.

Benefits of StencilQuik™

Eliminate hours of solder mask damage repair time for BGA sites while improving rework yield. StencilQuik™ serves as both your stencil and alignment device. As an added bonus the stencil acts as an insulator between interconnects preventing shorts between balls thereby increasing the reliability of the reworked device. The benefits of StencilQuick™ process are many:

- Eliminates "smearing" of the solder paste print pattern as the StencilQuick™ never gets lifted off the PCB

- Provides the lowest cost method for area array device placement as stencil cleaning costs are eliminated, scrap due to improper device placement is greatly reduced and the time required to align and place a device is cut significantly

- Allows you to rework area array devices in very "tight" areas on the PCB that are not possible with a metal stencil

- Allows you to rework area array devices with solder resist irregularities. The StencilQuick™ acts as a mask for damaged solder mask areas underneath a BGA. This eliminates the time required to tediously repair damaged mask while preventing "shorting" between balls

- StencilQuick™ allows you to rework area array devices on warped boards as the stencil is held in intimate contact with the PCB when the solder paste or flux is applied.

- StencilQuick™ features a built-in spacer which prevents excessive solder paste collapse and provides a minimum stand off height between the area array device and the PCB

- StencilQuick™ acts as an insulating barrier between solder balls as the solder paste masks adjacent apertures increasing placement reliability

- StencilQuick™ allows you to more quickly and correctly align a high lead count leaded SMT component increasing rework throughsut

- Simplifies BGA placement as you can "feel" the device settle into the apertures of the StencilQuick™.

- Allows you to replace your own BGAs or CSPs-without special training or large capital equipment expenditures

StencilQuik™ allows you to rework a BGA even in tight spaces not accommodated with a metal stencil.

StencilQuik™ eliminates the hassle of cleaning stencils.

StencilQuik™ eliminates hours of tedious mask repairs underneath BGAs.

StencilQuik™ eliminates multiple paste print operations due to dirty stencils.

This is how to order

To order your custom BGA rework StencilQuik please select the Ball Count (The price is based on the ball count) and upload the datasheet or Gerber file for your BGA component.

The StencilQuik part number is optional. If you are providing the StencilQuik part number you do not need to upload any file.

And if you upload a file you don't need to provide the part number. But it is REQUIRED to provide at least ONE of both. Standard lead time is (5) business days, 24-48hr expedites are also available. Stencil Quik comes in a pack of 10 BGA rework stencils

specs

| Minimum Aperture Size | .002in (.05mm) |

| Stencil Material | .Plastic film with release liner. Adhesive is a low tack sticky note type of adhesive. |

| Minimum Pitch | .020in (0.3mm) |

| Maximum Stencil Size | Approx 4 x 4in (100mm x 100mm) |

We accept either standard GERBER files, part data sheets or CAD files.