Display 1 to 12 (of 12)

Three (3) heating zone reflow ovens for batch production runs utilizing our patented Horizontal ConvectionTM Heating technology for extremely uniform temperature profiling across the printed circuit board for enhanced process control. The GF-120HT is lead-free compatible for RoHS compliant soldering

The GF-12HT SMT Reflow Oven uses a patented Horizontal Convection™ technology that circulates heated air in each chamber around the printed circuit board front to back which increases the thermal efficiency and uniformity within each zone. This exposes the circuit boards to a uniform temperature profile along the entire SMT PCB assembly. Cyclonic generator speed is independently set in each zone.

Nitrogen inerting option (GF-12-N).

Nitrogen inerting option for GF-120 Series (model GF-120-N).

Status light tower option for GF-120 (model GF-SLT).

The Gold-Flow™ GF-B-HT Shuttle Batch oven was designed for prototyping printed circuit board assembly and batch production runs. Capable for lead or lead-free soldering.

While one PCB is being processed, another circuit board can be cooled and off-loaded, then a third board can be loaded and shuttled into the chamber for reflow

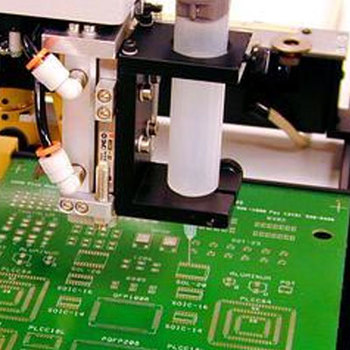

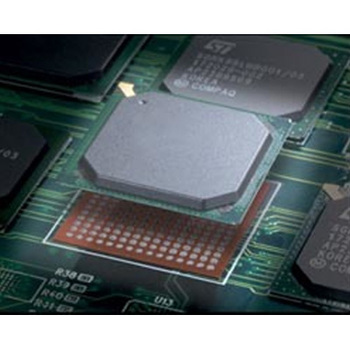

StencilQuik™ are flexible solder paste stencils manufactured from a polyimide film with a high temperature adhesive covered with a release liner. They serve as both your stencil and alignment device.

- StencilQuik comes in a pack of 10 BGA rework stencils

- Allows you to replace your own BGAs or CSPs without special training or large capital equipment expenditures

- Acts as an insulating barrier between solder balls as the solder paste masks adjacent apertures increasing placement reliability

- Simplifies BGA placement as you can "feel" the device settle into the apertures of the StencilQuik™